ID.ADD – THE END OF TUGGER TRAINS

Can a tugger train withstand the demands of customization?

As a result of digitization and globalization, ever higher demands are placed on companies, especially regarding cost and process efficiency. Increasing individualization of products and their ever-shorter life cycles require ever greater flexibility in aftercare.

We are convinced that a tugger train system cannot guarantee this quick and precise provision due to a certain inertia and the cyclical timetable.

Combination of innovative technologies

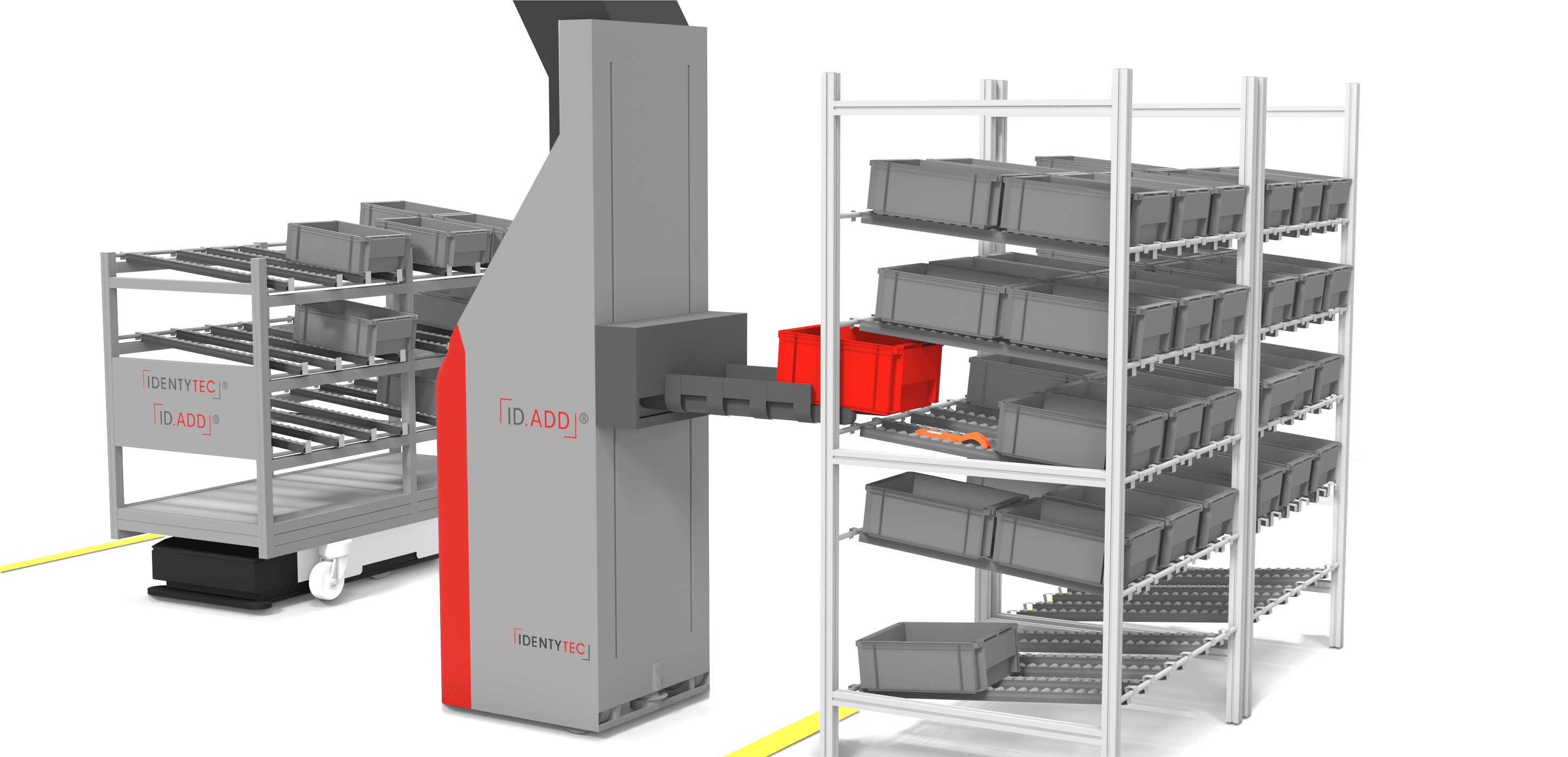

Fully automatic replenishment control and delivery of small and large load carriers (KLT / GLT) through driverless transport systems.

We set new standards through the integration and combination of the innovative technologies eKanban, Auto-ID products and AGV (Driverless Transport System).

This combination enables the necessary reaction speed, especially in unpredictable situations. The determination of requirements and subsequent reporting to a higher-level server is carried out reliably in connection with the customer’s own ERP system and through our long-established software-based eKanban system ID.EPC / ID.CONNECTOR.

The order of the retrieval system initiates the fully automatic retrieval of the materials as well as the subsequent exact provision of the required quantity in the supermarket or in the AKL (automatic small parts warehouse). Depending on the prioritization, the independently navigating AGVs transport the units that have already been pre-loaded in the supermarket. Then they send the replenishment units, broken down into individual containers, automatically and precisely using a lifting device directly into the individual channel of the production shelf.

If you have an AKL, the ID.ADD can fill itself automatically at the AKL. With this system solution, you can also organize the transport and provision of your large load carriers (GLT).

Your advantages

With our system we offer the possibility to call up 100% of your replenishment requirements fully automatically and in real time. The replenishment is also carried out automatically from the supermarket / train station / small parts warehouse to the production shelf or to the place of consumption.

In contrast to cost-intensive manual solutions or rigid tugger trains, material replenishment can take place in highly individualized assembly and production environments with high precision and flexibility.

This considerable dynamization of the replenishment process also ensures significant savings in space requirements by reducing the supply volumes at the point of consumption.

You achieve a smoothing and optimization of the delivery processes. Peaks, as they often occur especially when changing shifts, are completely eliminated.

Your delivery process becomes transparent and there is no over- or under-delivery. By eliminating manual processes, deliveries are only made when there is a real need.

We set new standards by integrating and combining the innovative technologies eKanban, Auto-ID products and AGV. Numerous combinable solutions to automate your ordering and delivery process up to 100%!